Asbestos can be a serious issue for developers, particularly of brownfield sites, with contamination occurring on the surface or more deeply in the ground. Assessing the type and amount of asbestos, and the risk it poses, requires specialist knowledge and experience, explains Harrison Group Environmental Associate Director Jon Archer.

Historically, many activities – from industry to agriculture and waste disposal – involved the use of the three main types of asbestos: Crocidolite (blue asbestos), Amosite (brown asbestos) and Chrysotile (white asbestos). Without careful management, these materials can find their way into the ground, following demolition of buildings and preliminary groundworks for example, presenting a serious issue for developers.

Investigation process

Like any other contaminated land investigation, the aim of an asbestos investigation is to identify the lateral and vertical distribution, quantity and type of asbestos in the ground (and also in the air). Importantly, while larger fragments of asbestos can sometimes be seen with the naked eye, soil can be contaminated by asbestos fibres that can only be identified under the microscope, in the laboratory.

CL:AiRE and the Joint Industry Working Group on Asbestos in Soil and Construction & Demolition Materials published Control of Asbestos Regulations 2012 Interpretation for managing and working with asbestos in soil and construction and demolition materials: Industry guidance in July 2016, which includes best practice approaches to investigations.

It recommends carrying out a desk study (as with any contaminated land investigation) to examine the site history, with the aim of identifying any previous use that could have involved asbestos, or any buildings that may contain, or demolished structures that may have contained, asbestos.

If there is potential for asbestos to be present, then a risk assessment is required before investigations begin and work must be carried out under an agreed plan of work (method statement).

Asbestos investigations do not normally require a licence, if contamination is deemed to be ‘Sporadic and low intensity (SALI) exposure’. However, there is no ‘safe’ level of exposure, so if it is suspected that asbestos is present, then investigations should be carried out by trained geoenvironmental specialists with relevant skills and experience.

Along with appropriate PPE, such as protective clothing and respiratory masks, air monitoring for asbestos fibres should also be carried out throughout the investigation to protect site staff and the general public. In dry conditions, water spraying can be used to keep potential asbestos dust and fibres from spreading over a wider area.

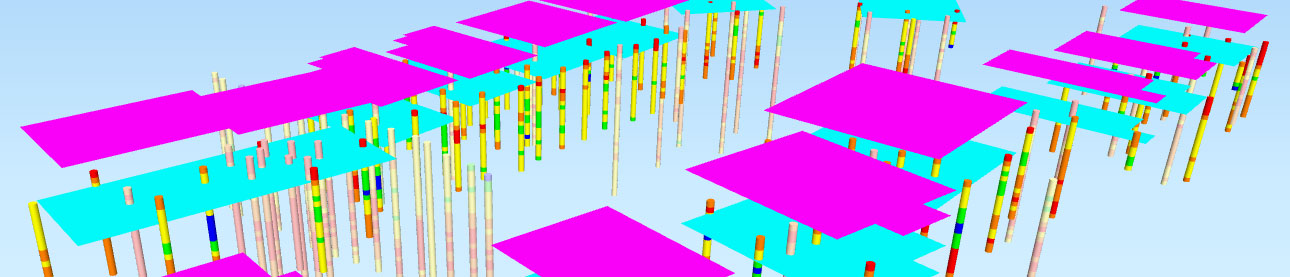

Intrusive investigations must provide good coverage of the shallow surface, to ensure that all made ground is investigated. Due to the likely widespread nature of asbestos contamination, trial pits or trenches (typically excavated by machine on a regular grid) are probably the best approach, as there is more chance of finding asbestos, followed by other techniques such as dynamic continuous sampling.

Samples collected should include any bulk fragments of potential asbestos found on the ground surface and in the ground, plus soil samples taken at regular intervals – this must be done carefully, to avoid introducing additional asbestos, so that the results are unbiased. Samples are sent to the laboratory to assess the amount and type of asbestos present.

It is worth noting that if asbestos is not identified in a sample, it does not necessarily mean that it is ‘clean’ or ‘uncontaminated’; it could be that the amount of asbestos is lower in the area from which it was taken and was not identified by the ‘point sampling’ approach.

Quantifying the risks

Following laboratory testing of samples, a quantitative risk assessment should be carried out, considering factors such as the nature and concentration of asbestos fibres and comparing these with background levels and likely exposure patterns.

CL:AiRE and the Joint Industry Working Group on Asbestos in Soil and Construction & Demolition Materials has also developed a decision support tool for receptor risk ranking, in accordance with the principles of CLR 11: Model procedures for the management of land contamination, for the qualitative assessment of asbestos risk using semi-quantitative methods supplemented by subjective assumptions.

These assessments can help determine the level of risk to the construction team, future occupants of the site and neighbours and, if necessary, inform the remediation strategy.

Remedial options

If remediation is required, a site-specific remediation statement needs to be developed and agreed with the local planning authority. Common approaches (which can be used in isolation or in combination), each with their own pros and cons, include:

- Soil stripping to a given depth, with soil passed through a mobile hand-picking line. This screening process aims to remove most of the bulk asbestos material. Screened soil should be sampled and tested before removal or reuse on site

- Excavation of the soil mass for off-site disposal or treatment

- Installation of a soil cover system in soft landscaping or garden areas. This involves excavating to a suitable depth, before placing a warning layer membrane, typically with 600mm of soil cover (subsoil and topsoil) above. The warning layer prevents mixing of the soil cover and the underlying made ground.

How Harrison Group Environmental can help

Soils contaminated with asbestos present a high risk to ground workers, future home owners and neighbouring residents. A comprehensive investigation, assessment and remediation strategy, developed and implemented by a specialist, is essential to ensure this risk is mitigated sufficiently.

Harrison Group Environmental has extensive experience in all aspects of contaminated land, including asbestos, carrying out desk studies, intrusive investigations, remediation and environmental risk assessments. Our competence and experience in assessing the risk and developing remediation strategies can save developers significant costs.

New guidance from the Association for Geotechnical and Geoenvironmental Specialists: Ground investigations – Work with asbestos risk assessement for the protection of intrusive ground investigation and laboratory personnel, is currently out for industry comment (April 2019).