Solar Farms Shine For Harrison Group

February 27, 2024

Solar Farms Shine For Harrison Group

The construction of solar farms is on the increase and they are now the most popular method in the UK for harnessing the sun’s rays to create energy.

Fields of photovoltaic panels are transforming the landscape and how we generate power, with the added bonus of contributing to a greener, more sustainable environment. Near future year-on-year growth in the industry is anticipated to be in the region of 25%.

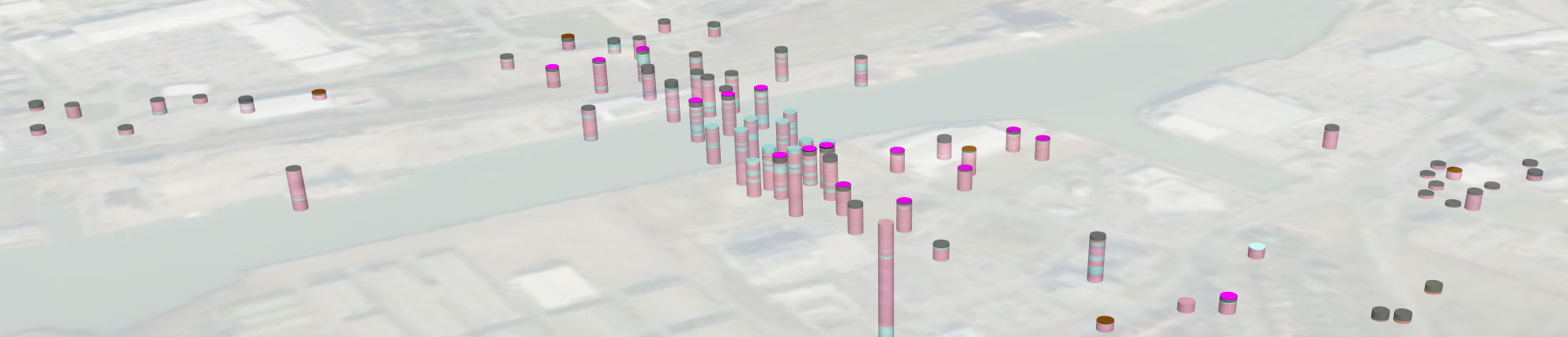

In the last two years, Harrison Group has successfully completed ground investigations on more than 25 proposed solar farms across the UK, working closely with a range of domestic and international clients. Site locations range from Somerset, Essex, Sheffield, Anglesey and north to the Scottish Borders.

Works have been undertaken to provide information for photovoltaic array foundations as well as associated infrastructure, including substations, transformer and inverter stations, construction compounds, and access roads.

Investigative works were tailored to the development proposals, history and ground conditions for each site.

Preliminary works included risk assessments, unexploded ordnance surveys, underground service tracing and coal mining authority permits where appropriate.

In-situ testing was comprehensive as was the physical and chemical soils testing.

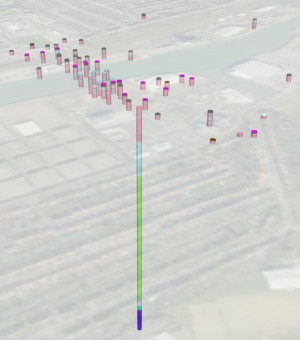

Driven steel piles are generally the preferred foundation solution for photovoltaic arrays. However, accurate assessment of drivability and load capacities must be undertaken to determine their suitability on a site-specific basis.

Harrison Group uses the latest equipment to carry out lateral and axial pile testing up to 6,000Kg and, in addition to this, laser technology is employed, ensuring highly accurate results.

For many of the sites, sacrificial test piles were installed to a range of depths. This allowed the completion of lateral and axial load testing, enabling the measurement of deformation and elastic rebound responses to the applied loads.

Full details of the scope of work and outcomes can be found here.

Lateral pile testing |

Axial pile testing |

Installation of steel pile for testing |

Axial pile testing |