Fen Drayton Road

Fen Drayton Road

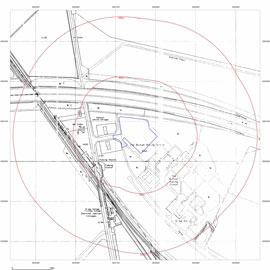

LOCATION: Swavesey, Cambs

PROJECT TYPE: Geoenvironmental investigation

VALUE: £13K

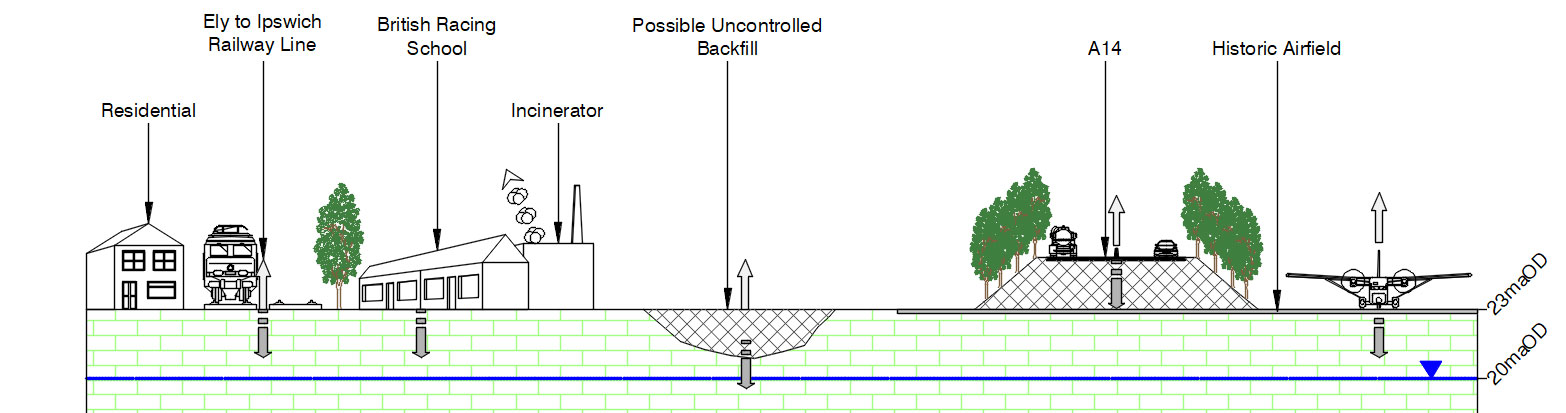

BACKGROUND

Land developers, as part of their due diligence, need to check, before construction commences, for the presence of ground gas such as methane and carbon dioxide, which can be hazardous to human health.

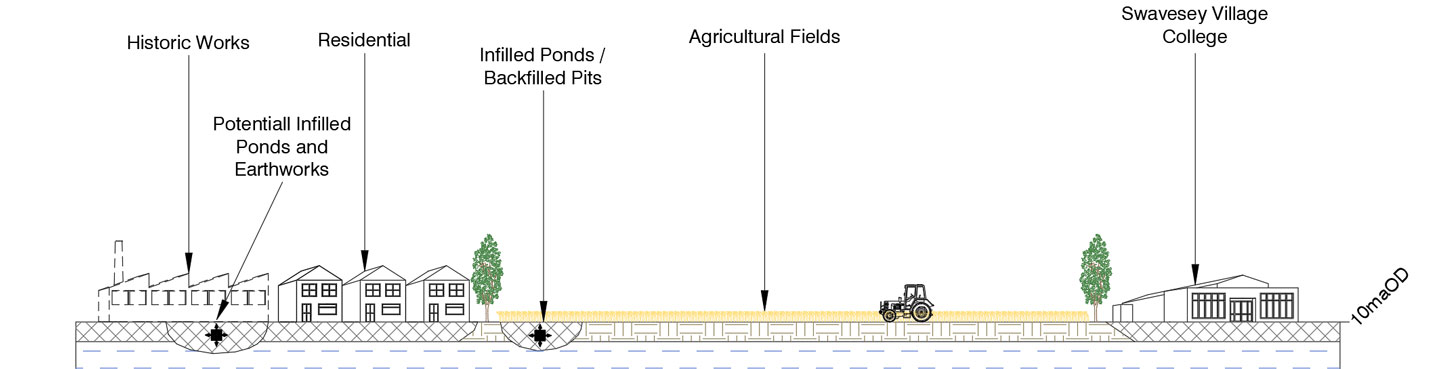

Bloor Homes commissioned Harrison Group to carry out such an investigation and report the findings on a 4.7ha agricultural site in Swavesey, near Cambridge. The site was earmarked for mixed-use residential development of 99 homes.

The results would be used in the design of roads and sewers, foundations, pavement construction and to conclude if any remediation measures would be required.

SCOPE OF WORK

Phase 1 Assessment (Desk Study) to produce a hazard assessment and conceptual ground model.

Phase 2 Investigation (Intrusive) to include:

- Soil sampling and standard penetration testing using a dynamic continuous sampling dual-purpose rig

- Machine-excavated trial pits with infiltration testing

- CBR testing

- Return visits for ground gas and flow monitoring

- Physical soil analysis to UKAS mCERTS standards

- Chemical analysis, general suite to include TPH, PAH and asbestos screening

- Interpretative report

Follow-on investigation for further ground characterisation:

- Continuous sampling boreholes with ground gas monitoring

- Detailed quantitative risk assessment with conceptual ground model, incorporating geology, potential ground gas sources & migration and exposure pathways

OUTCOME

Initial results indicated elevated levels of carbon dioxide and carbon monoxide, coupled with a high flow rate, requiring gas protection measures – subfloor venting and gas membranes.

Harrison Group recommended additional monitoring to assess the ground gas risk. Further characterisation of the ground would reduce overall construction risk, with the potential for reducing development costs. By combining the site model with proposed construction details and estimating ground gas equilibrium concentrations in the sub slab void, the ground gas risk was shown to be lower than originally envisaged. As a result of this, Bloor Homes was able to use the original design of precast concrete beam and block floors being in the construction.

There was no requirement for any further gas protection measures, saving considerable time and costs during construction.