PV Solar Farm Investigations

PV Solar Farm Investigations

LOCATION: England, Wales & Scotland

PROJECT TYPE: Geotechnical site investigations, pile testing

VALUE: £1.2M

BACKGROUND

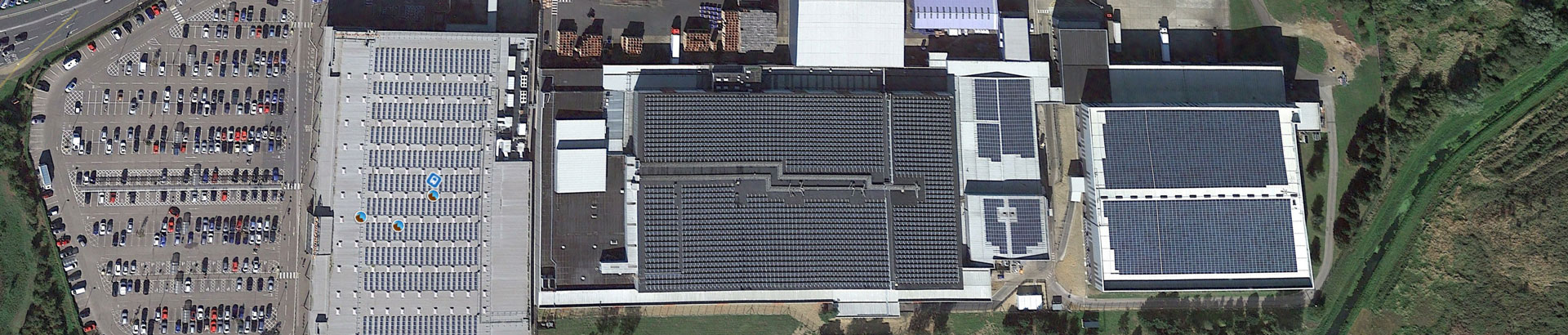

The renewable energy industry is rapidly expanding within the United Kingdom, with many photovoltaic array developments being undertaken to meet growing sustainable energy demands.

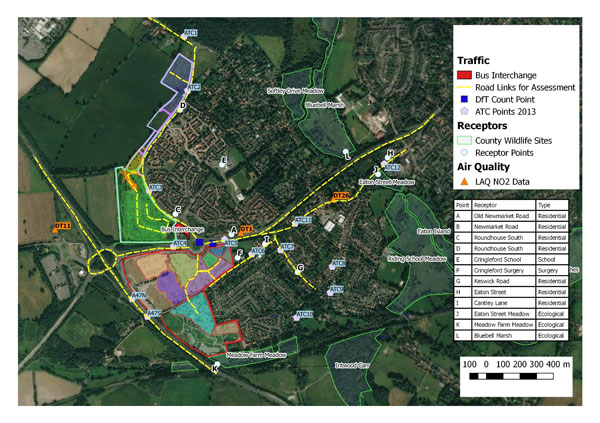

Harrison Group Environmental has successfully completed ground investigations on 25 proposed solar farms across the UK for a range of domestic and international clients in the last two years, at site locations ranging from Somerset, Essex, Sheffield, Anglesey, and the Scottish Borders.

Works were undertaken to provide information for photovoltaic array developments as well as associated infrastructure, including substations, transformer and inverter stations, construction compounds, and access roads.

A wide range of ground conditions were encountered, varying from quaternary age soils of glacigenic, river terrace, and head origin to bedrock geologies comprising mudstones, schist, and coal measures, with our investigation scopes tailored accordingly at each site.

SCOPE OF WORK

A range of preliminary works were required ahead of commencement of each ground investigation. These included:

- Undertaking preliminary risk assessments (phase 1 desk study).

- Provision of preliminary and detailed unexploded ordnance (UXO) threat assessments with on-site magnetometer surveys and supervision by specialist technicians.

Underground service tracing. - Obtaining coal mining authority permits for works within a backfilled historical open-cast coal mine.

The scope of the ground investigation comprised a range of methodologies, tailored to suit the specific development requirements and site conditions.

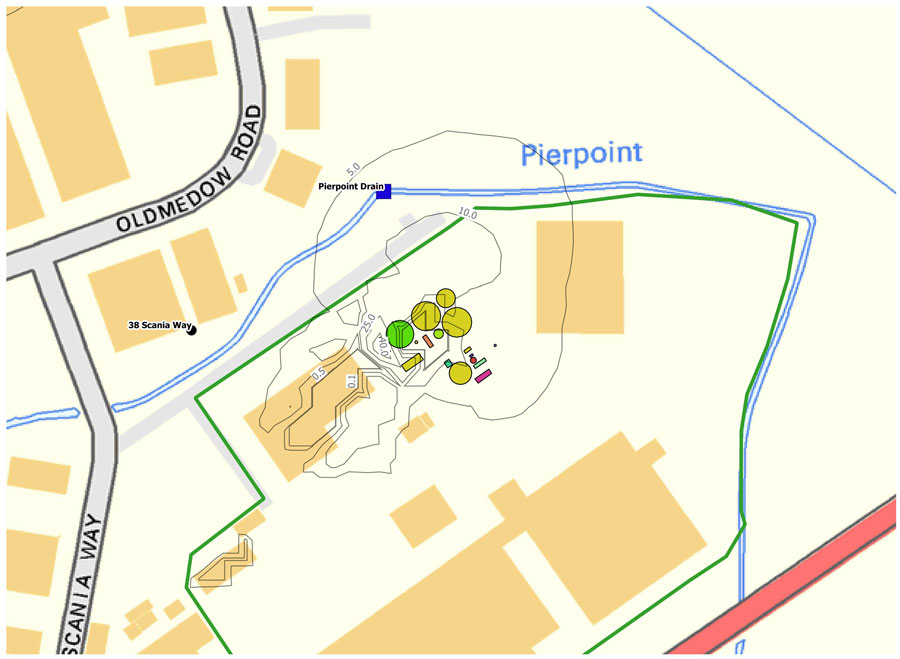

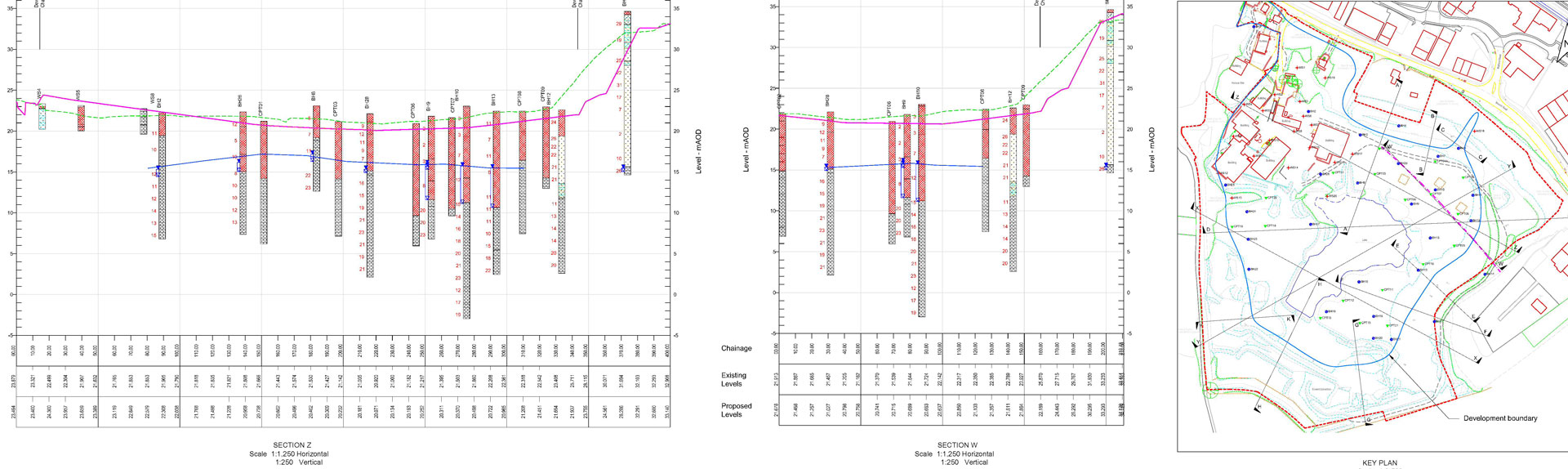

Exploratory investigation included rotary cored, cable percussive, and dynamically sampled boreholes, dynamic penetration testing, and machine excavated trial pits.

Detailed in-situ testing was undertaken at each site to provide quantitative data to inform the ground model and allow determination of geotechnical design parameters.

The test methods included:

- Plate bearing and California Bearing Ratio tests for crane lift and construction compound areas.

- TRL dynamic cone penetrometer and lightweight deflectometer tests along access routes and haul road alignments.

- Hand shear vanes.

- Pocket penetrometers.

- In-situ thermal resistivity testing was completed on proposed buried cable routes.

- In-situ electrical resistivity testing using a Wenner probe array.

A range of laboratory tests for geotechnical classification alongside thermal and electrical resistivity were undertaken on samples recovered from exploratory positions and imported soils, as well as geoenvironmental contamination suites and waste classification (WAC) testing.

Driven steel piles are generally the preferred foundation solution for photovoltaic arrays. However, accurate assessment of drivability and load capacities must be undertaken to determine their suitability on a site-specific basis.

Harrison Group uses the latest equipment to carry out lateral and axial pile testing up to 6,000Kg and, in addition to this, laser technology is employed, ensuring highly accurate results.

For many of the sites, sacrificial test piles were installed to a range of depths. This allowed the completion of lateral and axial load testing, enabling the measurement of deformation and elastic rebound responses to the applied loads.

OUTCOME

The investigations overcame a range of access restrictions and poor surface ground conditions to deliver results quickly and effectively to the clients, while minimising inconvenience and disturbance to landowners and local stakeholders.

Harrison Group also delivered interpretative reports confirming the geological and environmental baseline conditions, and information on hazards and constraints present at each site, which could impact the design and construction phases.

Detailed recommendations and advice were provided which would be incorporated by the client at the design stage.

This included geotechnical parameters for soil and rock, subgrade suitability for roads, shallow foundation solutions including bearing capacity, pile capacity (both in compression and tension) and pile driveability assessment.

All solar farm projects have been completed successfully by Harrison Group, with site works and written reporting all supported by a comprehensive quality management system.

View full details here.